Many shops have operators put the machine in single block mode and start to single step through the program. A CNC programmer would come along, drop off a program to the operator, sometimes providing only the G-code and a pencil, and from there the operator was expected to machine the part.

BRIDGING THE GAPįor many years, comparing design and manufacturing information has been the responsibility of design/mechanical and manufacturing engineers in the office, leaving the operators on the shop floor in the dark. Sometimes just adding useful software programs or applications can help small to medium-size shops access the latest smart technology trends and improve manufacturability on the shop floor. Not all shops have the capital to invest in the most advanced technology, nor do they always have the need. However, creating a digital twin often can be expensive and not always necessary. They contain a significant amount of information, including the dimensions and tolerances, design and operation notes, manufacturing data, and work instructions. It gives a worker, who may have never assembled a part before, the ability to digitally put together an assembly with step-by-step instructions and gives them a real-world experience where they can make mistakes without any repercussions.īeyond AR, digital twins also are becoming more sophisticated and advanced, acting more like a real part than a digital carbon copy. For workers who are new to the field, AR technology is a great way to introduce and familiarize them with changing work instructions and protocols. Integrating automation, robotics, artificial intelligence, and sensors is helping to improve manufacturing processes.Īugmented reality (AR) is also being used by large companies that are training shop floor workers using AR glasses and systems to help improve assembly process flow.

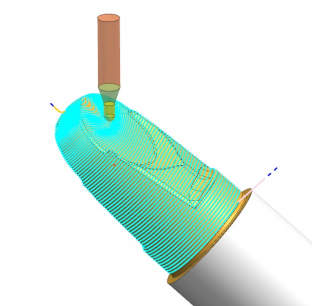

For example, aerospace giants like Boeing and Airbus have had smart factory initiatives in place for more than five years. Many large manufacturing companies are far along in their transition into the digital transformation. Today’s smart manufacturing software and applications are making it easier for these workers to adapt in order to leverage the power of Industry 4.0 and digitization of work flow. One way that this is done is by developing clear work instructions for CNC machinists and shop floor operators that allow them to systematically work through projects with ease and effectiveness. In an industry where time is money, machine shops are focused on enhancing productivity as a means to boost profitability. Manufacturing is in the midst of a digital transformation. CAMWorks ShopFloor includes full step-through toolpath simulation so that operators can see each move that the tool is going to make before the part is run on the machine.

0 kommentar(er)

0 kommentar(er)